Know Your Emitter #2

Finding the right material

A new year is here. What a great time to learn something new! This little educational series is part of FIT’s Electrospray Academy. If you find it useful, please let us know ;)

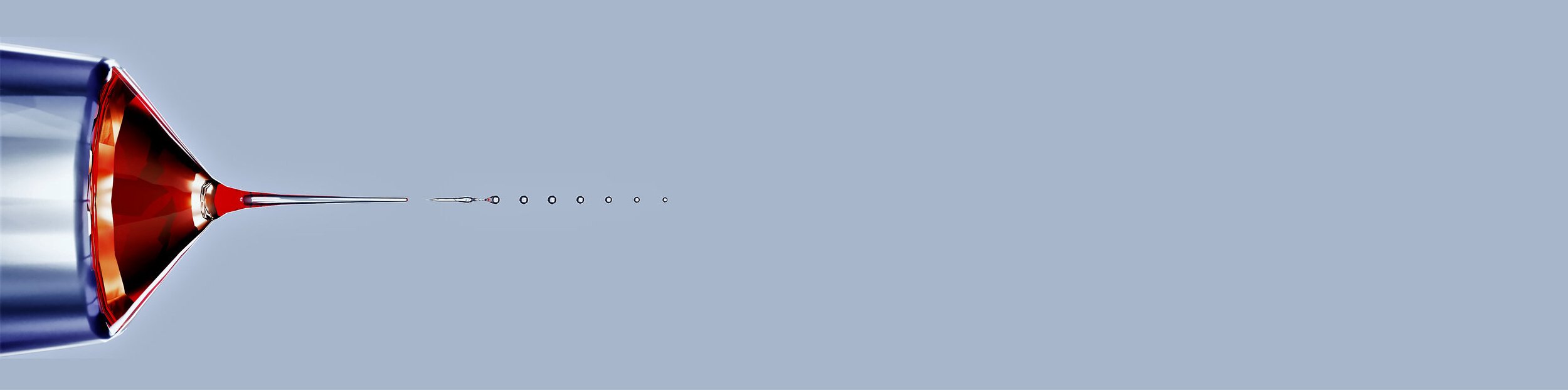

The electrospray (ES) emitter is an essential part of a high-res mass spectrometry system. The quality of the data is linked to a reliable ES. Despite its central importance, this tiny piece of equipment isn’t well known. So here are some interesting facts about it.

LESSON #2

What’s it made of?

An emitter can be made out of plastic, metal, fused silica (glass), several of them combined.. or even paper! Choosing the right type may be crucial for achieving optimal performance of the detection system.

Metal

They are resistant and robust. Good for high flow.

Silica

Versatile and precise. Appropriate for high and low flow. Ideal for nanoelectrospray and HRMS. More fragile than metal.

Combined

Silica capillaries with metal tips.

Others

Multiple tips. Up to 8 simultaneous tips in parallel. Robust, good for higher flows.

3D microlithography. For ID < 10 μm. Still in experimental phase. https://aip.scitation.org/doi/full/10.1063/5.0066619

Multiplexed. For highly conductive and corrosive fluids.

Coatings

Some emitters have an inner coated layer, in the surface in contact with the sample. This presents several issues, namely:

Depending on the polarity of the samples used, it may make the capillary more prone to clogging

It wears off eventually

However it may present a significant advantage, and potentially the coating formula could be optimized for certain types of molecules, allowing for the manufacturing of highly customized pieces.

In lesson #1 we discussed the emitter’s dimensions. Next day we’ll talk about the emitter’s geometry, and how it can affect its performance.

Stop being that guy who doesn’t know his emitters (there’s one in every party). Stay tuned to Electrospray Academy!

Want to know more about ES emitters?